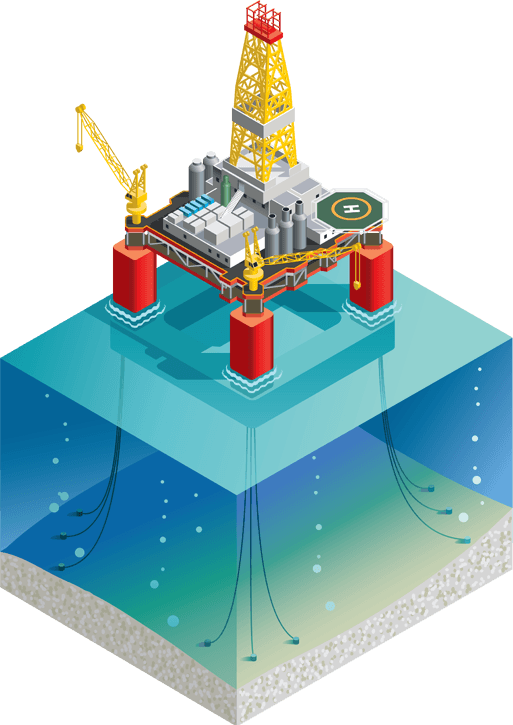

Drillship and/or Semisubmersible Rig

At its offshore locations, Murphy Oil drills for hydrocarbons in deepwater with drillships or semisubmersible rigs, and then pumps oil and natural gas up through pipes on production platforms. The oil and natural gas is transported to shore through a pipeline or to a sailing vessel known as a floating production system (FPS), which delivers the oil and natural gas to onshore facilities for processing and refining.

Oil Storage

After hydrocarbons are produced to the surface, they are held in third-party storage tanks until transported via pipelines, trucks or railcars to refineries for processing into products such as gasoline, diesel, jet fuel and other petrochemical materials before the components are delivered to various end users.

Floating Production System (FPS)

Owned by a third-party company, a floating production system (FPS) is located offshore in areas with little infrastructure. The vessel receives oil and natural gas fluids produced from a subsea reservoir through nearby subsea wells and processes the hydrocarbons before offloading to a shuttle tanker.

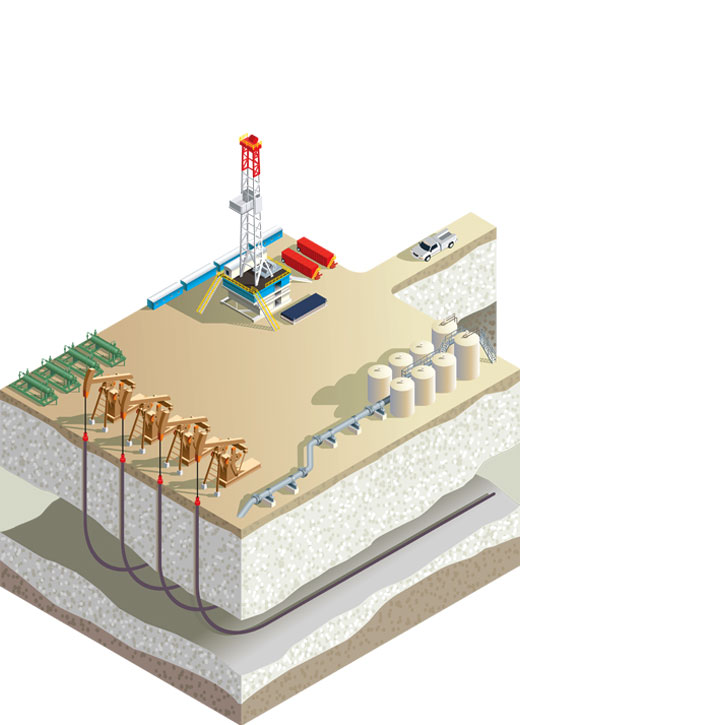

Onshore Rig

At its onshore locations, Murphy drills and hydraulically fractures oil and natural gas formations. The company safely produces the hydrocarbons by directing the oil and natural gas from the subsurface rock into flowlines and surface-level storage facilities. The oil and natural gas is later transported by pipelines, trucks or railcars to be processed at refining facilities for end users.

Pump Jack

Murphy utilizes rod lift as one of its onshore artificial lift designs when reservoir pressures are unable to push oil and natural gas to the surface naturally. This process involves a downhole pump with a plunger and valve assembly, which is connected to a string of rods inside the production tubing. The rods are mechanically lifted at the surface through a pump jack, which pulls oil out of the wellbore up to the surface before pumping to storage facilities through pipelines. The oil is later transported by pipelines, trucks or railcars to be processed at refining facilities for end users.

Buildings

The oil and natural gas that Murphy produces is sold to refineries, where it is processed before the products such as gasoline, diesel, jet fuel and other petrochemical materials are delivered to various end users. In this case, natural gas is used to heat homes and offices.

Drillship and/or Semisubmersible Rig

At its offshore locations, Murphy Oil drills for hydrocarbons in deepwater with drillships or semisubmersible rigs, and then pumps oil and natural gas up through pipes on production platforms. The oil and natural gas is transported to shore through a pipeline or to a sailing vessel known as a floating production system (FPS), which delivers the oil and natural gas to onshore facilities for processing and refining.

Oil Storage

After hydrocarbons are produced to the surface, they are held in third-party storage tanks until transported via pipelines, trucks or railcars to refineries for processing into products such as gasoline, diesel, jet fuel and other petrochemical materials before the components are delivered to various end users.

Buildings

The oil and natural gas that Murphy produces is sold to refineries, where it is processed before the products such as gasoline, diesel, jet fuel and other petrochemical materials are delivered to various end users. In this case, natural gas is used to heat homes and offices.

Floating Production System (FPS)

Owned by a third-party company, a floating production system (FPS) is located offshore in areas with little infrastructure. The vessel receives oil and natural gas fluids produced from a subsea reservoir through nearby subsea wells and processes the hydrocarbons before offloading to a shuttle tanker.

Onshore Rig

At its onshore locations, Murphy drills and hydraulically fractures oil and natural gas formations. The company safely produces the hydrocarbons by directing the oil and natural gas from the subsurface rock into flowlines and surface-level storage facilities. The oil and natural gas is later transported by pipelines, trucks or railcars to be processed at refining facilities for end users.

Pump Jack

Murphy utilizes rod lift as one of its onshore artificial lift designs when reservoir pressures are unable to push oil and natural gas to the surface naturally. This process involves a downhole pump with a plunger and valve assembly, which is connected to a string of rods inside the production tubing. The rods are mechanically lifted at the surface through a pump jack, which pulls oil out of the wellbore up to the surface before pumping to storage facilities through pipelines. The oil is later transported by pipelines, trucks or railcars to be processed at refining facilities for end users.

Onshore

Offshore

Murphy also has several exploration prospects across 58 blocks in the Gulf of America to augment its producing infrastructure with nearfield exploration. Other offshore exploration blocks are located in Brazil, Vietnam and Côte d’Ivoire.

Operations Map

Environmental Protection & Conservation